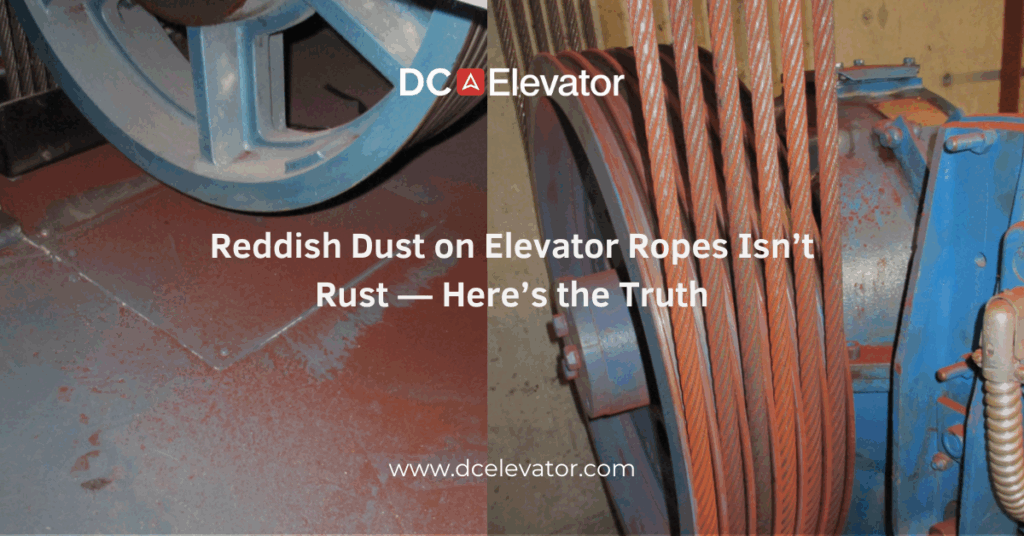

If you’ve ever opened your elevator machine room or looked inside the hoistway and noticed a reddish or rusty-looking dust on the elevator ropes, your first thought might be: “Are my ropes corroding?” It’s a common concern among building owners and facility managers — after all, elevator ropes play a crucial role in passenger safety.

The good news? That reddish dust isn’t necessarily rust. In most cases, it’s something far less alarming and completely normal. Understanding the difference can help prevent unnecessary alarm and maintenance costs while ensuring your elevator remains in top operating condition. Let’s explore what this dust really is, why it appears, and how regular maintenance can help you keep your system running smoothly.

What the Reddish Dust Really Is

Despite its rusty appearance, the reddish dust you see on elevator ropes is typically oxidized lubricant residue — not corrosion. Elevator ropes are lubricated to reduce friction between the steel strands and the sheaves (the grooved pulleys that move the elevator).

Over time, as the lubricant breaks down and mixes with tiny metal particles caused by normal wear, it forms a fine reddish-brown dust. This residue often settles on nearby surfaces or accumulates along the ropes, giving the illusion of rust.

This process is a natural part of rope wear and lubrication, not necessarily a sign of damage or neglect.

When It Might Actually Be a Problem

While the reddish dust is usually harmless, there are instances when it can indicate deeper issues. If you notice the dust accompanied by:

-

Visible rope pitting or deep discoloration

-

Frayed strands or uneven tension

-

Unusual noises during operation

…it could be a sign that the ropes are deteriorating beyond normal wear. In such cases, it’s essential to have a certified elevator technician conduct a rope inspection and test the rope tension and lubrication levels.

Ignoring true rope corrosion or wear can lead to unsafe operating conditions, costly breakdowns, or failed inspections down the road.

How Regular Maintenance Prevents Misdiagnosis

Routine elevator maintenance and rope cleaning can prevent confusion and unnecessary replacement costs. Properly trained technicians inspect ropes for wear patterns, verify lubrication quality, and determine if the dust buildup is normal residue or a sign of damage.

Lubricant choice also plays a key role. Using a lubricant that’s not compatible with your rope material can accelerate residue buildup or cause improper traction. Partnering with a reliable service provider ensures the correct lubricants and cleaning methods are applied to prolong rope life and maintain efficiency.

Modernization or periodic upgrades can also reduce rope wear by improving drive systems, alignment, and tension control.

Best Practices for Building Owners

Facility managers and building owners can help minimize issues by:

-

Scheduling regular rope cleaning and lubrication checks

-

Maintaining proper machine room ventilation to reduce dust accumulation

-

Reviewing maintenance reports for rope condition notes

-

Asking for a rope sample inspection if abnormal wear is suspected

Proactive maintenance not only ensures safety but also helps you avoid unnecessary costs caused by premature replacements or misdiagnosed corrosion.

The presence of reddish dust on elevator ropes may look concerning, but it’s usually a natural byproduct of routine wear and lubricant oxidation — not a sign of rust or corrosion. Still, regular inspections and maintenance are essential to confirm your elevator’s ropes are in good condition and performing safely.

If you’ve noticed reddish dust on your elevator ropes and aren’t sure what it means, our team can provide a professional assessment to determine whether it’s normal residue or a sign of wear. Contact us today to schedule an elevator inspection and ensure your system stays safe, efficient, and compliant.